Ingemuva

Kukhishwe inguqulo entsha ye-UL 1642. Okunye ukuhlolwa komthelela osindayo kwengezwa kumaseli esikhwama. Izidingo eziqondile yilezi: Kuseli lesikhwama elinomthamo omkhulu kuno-300 mAh, uma kuphumelele ukuhlolwa komthelela osindayo kungazange kuphasiswe, angenziwa ngaphansi kokuhlolwa kwe-Section 14A round rod extrusion.

Isikhwama sesikhwama asinaso isikhwama esiqinile, okuvamise ukuholela ekuqhekekeni kweseli, ukuphuka kompompi, udoti endizela ngaphandle kanye nomunye umonakalo omkhulu odalwe ukwehluleka ekuhlolweni komthelela osindayo, futhi kwenza kube nzima ukuthola isifunda esifushane sangaphakathi esibangelwa iphutha ledizayini noma ukungasebenzi kahle kwenqubo. . Ngokuhlolwa kwe-round rod crush, amaphutha okungenzeka kuseli angatholwa ngaphandle kokulimaza isakhiwo seseli. Ukubuyekezwa kwenziwa nalesi simo kucatshangelwa.

Ukugeleza kokuhlola

- Isampula ishajwe ngokugcwele njengoba kunconywe umenzi

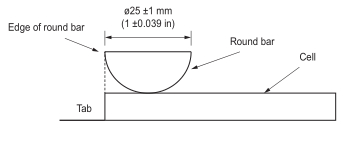

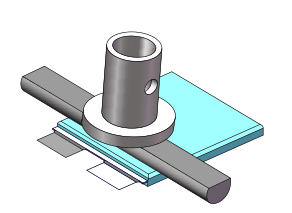

- Beka isampula endaweni eyisicaba. Beka induku yensimbi eyindilinga enobubanzi obungama-25±1mm ngaphezulu kwesampula. Unqenqema lwenduku kufanele luqondaniswe nonqenqema olungaphezulu lweseli, ne-eksisi eqondile i-perpendicular kuthebhu (FIG. 1). Ubude benduku kufanele okungenani bube ububanzi obungu-5mm kunomkhawulo ngamunye wesampula yokuhlola. Kumaseli anamathebhu amahle noma anegethivu ezinhlangothini ezibhekene, uhlangothi ngalunye lwethebhu ludinga ukuhlolwa. Uhlangothi ngalunye lwethebhu kufanele luhlolwe kumasampuli ahlukene.

- Ukulinganisa ukushuba (tolerance±0.1mm) wamaseli kufanele enziwe ngaphambi kokuhlolwa ngokuhambisana neSithasiselo A se-IEC 61960-3 (Amaseli esibili namabhethri aqukethe i-alkaline noma amanye ama-electrolyte angewona ama-acidic - Amaseli aphathekayo wesibili e-lithium namabhethri - Ingxenye 3: I-Prismatic ne-cylindrical lithium yesibili amaseli namabhethri)

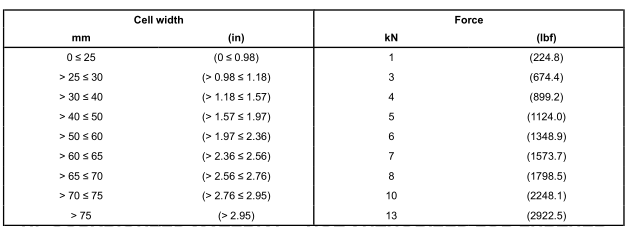

- Khona-ke ukucindezela kokucindezela kusetshenziselwa induku eyindilinga futhi ukufuduka endaweni eqondile kubhalwe (FIG. 2). Ijubane elinyakazayo lepuleti lokucindezela akufanele libe likhulu kuno-0.1mm/s. Lapho ukuguqulwa kweseli kufinyelela ku-13±U-1% wogqinsi lweseli, noma ingcindezi ifinyelela kumandla aboniswe kuThebula 1 (ugqinsi oluhlukile lwamaseli luhambisana namanani ahlukene wamandla), misa ukususwa kwepuleti bese ulibamba ama-30s. Ukuhlolwa kuyaphela.

- Akukho mlilo noma ukuqhuma kwamasampula.

Ukuhlaziya kokuhlola

- Ukukhethwa kwendawo ye-extrusion: indawo yethebhu yesigxobo ngokuvamile iyindawo ebuthaka yeseli yesikhwama, futhi indawo yethebhu ithwala ukucindezelwa okukhulu lapho incindwa. Izizathu yilezi:

a) Ukusatshalaliswa kogqinsi okungalingani (ubukhulu obungalingani phakathi kwethebhu yesigxobo kanye nento esebenzayo ezungezile kuholela ekusabalaliseni kwengcindezi okungalingani)

b) Amamaki okushisela endaweni yethebhu (ukusabalalisa ingcindezi endaweni yokushisela kanye nephoyinti elingashiseli)

- Ukukhethwa kwenduku eyindilinga: Ububanzi benduku eyindilinga bungama-25mm. Leli nani likhethwa ukumboza yonke indawo yethebhu yesigxobo esitokisini (ikakhulukazi indawo emboze ijoyinti le-pole tab solder).

- 13±1% deformation: Njengamanje, ukujiya kweseli thinnest emakethe kungu-2mm. Ngenxa yethonya lokuvaleka kwebhethri noma inqubo yokupakisha, kudingeka okungenani uhlobo oluguquguqukayo elingu-8% ukuze kucindezelwe kwijoyinti ye-pole tab solder, kodwa kuzoholela ngokuqondile ekuqhekekeni kwe-electrode uma uhlobo oluguquguqukayo lukhulu kakhulu. Inani elingu-13±Kukhethwe i-1% kulokhu kubuyekezwa, kubhekiselwa ekuguquguqukeni okuphakathi okungu-15% ekuhlolweni kwe-extrusion ku-IEC 62660-3.

- Ukukhetha isampuli: Kufanele kuqashelwe ukuthi lokhu kuhlolwa okwamaseli ezikhwama kuphela amandla awo angaphezu kuka-300mAh futhi angazange ashaywe izinto ezisindayo. Kudingeka amasampula ama-5. Amaseli angama-cylindrical noma ama-prismatic namaseli esikhwama ashaywe izinto ezisindayo't kudingekile ukuthi kucatshangelwe lokhu kuhlolwa.

Isifinyezo

Ukuhlolwa okusha kwe-extrusion yenduku eyindilinga kuhlukile kokwasekuqaleni kokuhlolwa kwe-extrusion kwe-UL 1642. Ukuhlolwa kwe-extrusion kwasekuqaleni ukusebenzisa i-flat extrusion, nokusebenzisa amandla angashintshi angu-13kN ngaphandle kokubamba isikhathi. Isebenza kuzo zonke izinhlobo zeseli. Lokhu kuhlolwa kuhlola amandla emishini yeseli lilonke (kuhlanganise necala) kanye nekhono layo lokumelana nokucindezeleka komshini; kuyilapho i-extrusion yenduku eyindilinga ihlola kuphela ingxenye yeseli, indawo encane ye-indenter izokwenza ukucindezeleka kwangaphakathi kugxile, kube lula ukuholela kumjikelezo omfushane wangaphakathi. Ikakhulukazi, isikhundla se-extrusion sikhethwa endaweni ebuthakathaka ye-pole tab welding, engaphenya kangcono ukusebenza kokuphepha kweseli.

Njengamanje, le ndlela yenduku eyindilinga iphinde isetshenziswe ekuhlolweni kwe-extrusion yeseli yesikhwama ku-GB 31241. I-MCM inolwazi olucebile lokuhlola kulo msebenzi.

Isikhathi sokuthumela: Nov-16-2022