Ingemuva

Ukusatshalaliswa okushisayo kwemojuli kuba nezigaba ezilandelayo: Ukunqwabelana kokushisa ngemva kokuhlukunyezwa kokushisa kweseli, ukubaleka kokushisa kweseli kanye nokubaleka kwemojuli yokushisa. Ukubaleka okushisayo kungqamuzana elilodwa akunamandla; kodwa-ke, lapho ukushisa kusakazeka kwamanye amaseli, ukusabalalisa kuzodala umphumela we-domino, okuholela ekubalekeni okushisayo kwe-module yonke, ukukhulula amandla amakhulu. Umfanekiso 1umbukisos umphumela wokuhlolwa kwe-thermal runaway. Imojula iyavutha ngenxa yokusabalalisa okungenakuvinjelwa.

I-conductivity yokushisa ngaphakathi kweseli izohluka ngokuya ngezinkomba ezihlukene. I-coefficient ye-conductivity yokushisa izoba phezulu ekuqondeningokuhambisanange-roll core yeseli; kuyilapho isiqondiso esime mpo ku-roll core sinokusebenza okuphansi. Ngakho-ke ukusabalala okushisayo kusuka ohlangothini kuya kolunye phakathi kwamaseli kuyashesha kunalokho okwenzeka ngamathebhu kuya kumaseli. Ngakho-ke ukusakazeka kungabonakala njengokusakazeka kohlangothi olulodwa. Njengoba amamojula ebhethri edizayinelwe ukuminyana kwamandla aphezulu, isikhala phakathi kwamaseli siya siba sincane, okuzokwenza kube kubi ukusakazeka kokushisa. Ngakho-ke, ukucindezela noma ukuvimbela ukusabalala kokushisa kumojula kuzobhekwa njengeumphumelaive indlela yokunciphisa izingozi.

Indlela yokucindezela ukubaleka okushisayo kumojuli

Singakwazi ukuvimbela ukubaleka okushisayo ngokuqhubekayo noma ngokuthula.

Ukucindezela okusebenzayo

Ukucindezelwa okusebenzayo kokusabalala kwe-thermal kusekelwe kakhulu ohlelweni lokuphatha okushisayo, njenge:

1) Setha amapayipi okupholisa phansi noma emaceleni angaphakathi emojuli, bese ugcwalisa uketshezi olupholisayo. Ukugeleza koketshezi olupholile kunganciphisa ngempumelelo ukusakazeka.

2) Misa amapayipi okucima umlilo phezulu kwemojuli. Uma kubaleka okushisayo, igesi lokushisa eliphezulu elikhishwe ebhethrini lizobangela amapayipi ukuthi afafaze isicisha-mlilo ukuze acindezele ukusakazeka.

Kodwa-ke, ukuphathwa kwe-thermal kudinga izingxenye ezengeziwe, okuholela ezindleko eziphakeme kanye nokuminyana kwamandla aphansi. Kukhona futhi ukuthi kungenzeka ukuthi uhlelo lokuphatha lungasebenzi.

Ukucindezelwa okwenziwayo

Ukucindezelwa kwe-Passive kusebenza ngokuvimbela ukusakazeka nge-adiabatic material phakathi kwamaseli abalekayo ashisayo namaseli avamile.

Ngokujwayelekile impahla kufanele ibonakale kokuthi:

- I-conductivity ephansi yokushisa. Lokhu okokwehlisa isivinini sokusabalala kokushisa.

- Ukumelana nokushisa okuphezulu. Impahla akufanele ixazulule ngaphansi kokushisa okuphezulu futhi ilahlekelwe amandla okumelana nokushisa.

- Ukuminyana okuphansi. Lokhu okokwehlisa umthelela wezinga levolumu yamandla kanye nenani lamandla amakhulu.

Impahla efanelekile ingavimba ukubhebhetheka kokushisa futhi imunce ukushisa.

Ukuhlaziywa kwezinto

- I-Airgel

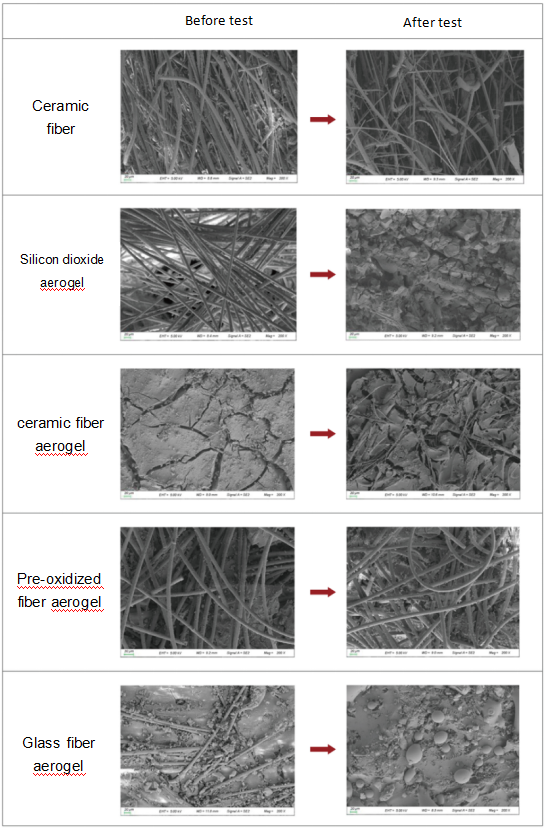

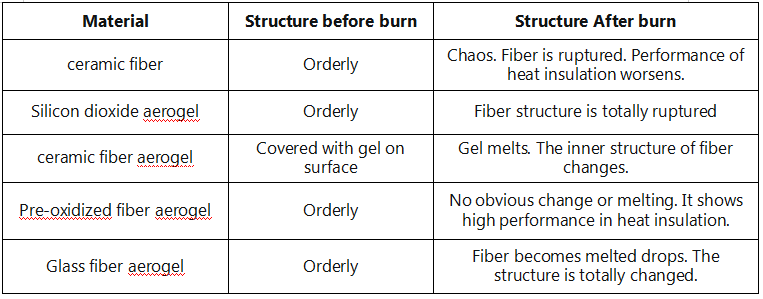

I-Airgel ibizwa ngokuthi "into elula kakhulu yokushisa ukushisa". Kwenziwa kahle ekufakeni ukushisa kanye nesisindo sokukhanya. Isetshenziswa kakhulu kumojula yebhethri yokuvikela ukusabalalisa okushisayo. Kunezinhlobo eziningi ze-aerogel, njenge-silicon dioxide aerogel, i-aerogel, i-glass fibre airgel kanye ne-pre-oxidized fiber. I-Airgel heat insulation layer yezinto ezihlukene inomthelela ohlukahlukene ekubalekeni okushisayo. Lokhu kungenxa yokuthi izinhlobonhlobo ze-coefficient ye-thermal conductivity, ehlobene kakhulu nesakhiwo sayo esincane. Umfanekiso wesi-2 ubonisa ukubukeka kwe-SEM yezinto ezahlukene ngaphambi nangemuva kokusha.

Ucwaningo lubonisa ukuthi nakuba ukufakwa kokushisa kwefayibha kuphansi ngentengo, ukusebenza kokuvimbela ukusakazeka kokushisa kubi kunempahla ye-airgel. Phakathi kwezinhlobo ezahlukene zezinto ze-airgel, i-pre-oxidized fibre airgel yenza kahle kakhulu, njengoba igcina isakhiwo ngemva kokusha. I-Ceramic fiber airgel nayo yenza kahle ekushiseni.

- Izinto zokushintsha isigaba

Impahla yokushintsha isigaba nayo isetshenziswa kabanzi ukucindezela ukusakazwa kwe-thermal runnaway ngenxa yokugcinwa kwayo kokushisa. I-Wax iyi-PCM evamile, enezinga lokushisa elizinzile lokushintsha kwesigaba. Ngesikhathi sokushisabaleka, ukushisa kukhishwa kakhulu. Ngakho-ke i-PCM kufanele ibe phezuluukusebenzalokumunca ukushisa. Kodwa-ke, i-wax ine-conductivity yokushisa ephansi, ezothonya ukumunca ukushisa. Ukukhuthaza ukusebenza kwayo, abacwaningi bazama ukuhlanganisa i-wax nezinye izinto, njengokwengeza izinhlayiya zensimbi, sebenzisa igwebu lensimbi ukulayisha i-PCM, engeza.i-graphite, ishubhu le-carbon nano noma i-graphite enwetshiwe, njll. I-graphite enwetshiwe inganqanda ilangabi elibangelwa ukugijima okushisayo.

I-Hydrophilic polymer nayo iwuhlobo lwe-PCM lokuvimbela umzila wezindiza oshisayo. Izinto ezivamile ze-hydrophilic polymer yilezi: i-colloidal silicon dioxide, i-saturated calcium chloride solution,I-Tetraethyl phosphate, utherai-phenyl hydrogen phosphate,si-polyacrylate ye-odium, njll.

- Izinto ezixubile

Ukubaleka okushisayo akukwazi ukuvinjelwa uma sithembele kuphela ku-aerogel. Ukuze ngempumelelovikelaukushisa, sidinga ukuhlanganisa i-airgel ne-PCM.

Ngaphandle kwe-hybrid material, singakwazi futhi ukwakha i-multi-layer material coefficients ehlukahlukene ye-thermal conductivity ezindaweni ezahlukene. Singasebenzisa okokusebenza okuphezulu kwe-thermal conductivity ukuze sikhiphe ukushisa kumojuli, futhi sibeke okokufaka ukushisa phakathi kwamaseli ukuze sikhawulele ukusakazeka kokushisa.

Isiphetho

Ukulawula ukusakazwa kwe-thermal runnaway kuyindaba eyinkimbinkimbi. Abanye abakhiqizi benze izixazululo ezithile zokucindezela ukusabalala kokushisa, kodwa basafuna okuthile okusha, ukuze behlise izindleko kanye nomthelela ekukhuleni kwamandla. Sisagxile ocwaningweni lwakamuva. Akekho“super material” okungavimba ngokuphelele ukubaleka okushisayo. Kudinga ukuhlolwa okuningi ukuze uthole izixazululo ezingcono kakhulu.

Isikhathi sokuthumela: Mar-10-2023